Modular Cleanroom Solutions

Maximize Productivity with Our High-Performance Cleanrooms

- Aerospace

- Electronics

- Pharmaceutical

- Healthcare

By ensuring rapid deployment, customized designs, and optimal performance for your critical applications, you can focus on production.

Customizations

Classifications

ISO4 – ISO9 Compliance

Wall Types

Acrylic / Tempered Glass

Antistatic Soft PVC Wall

Sandwich Panel (Non-Transparent)

Walls come with Stainless Steel or Aluminum Frames

View Window

Double-sided Tempered Glass

Transparent Walls

Door Types

PVC Strip Doors

Tempered Glass / Acrylic Door

Stainless Steel / Aluminum / Sandwich (Cardboard / Styrofoam – options inside)

Doors come with sliding or hinged options.

Dimensions

There are no limitations to the size, height, or span. Prefabricated cleanrooms are fully customizable.

With or Without Floor Options

Floor can be textured or flat. Elevated floor for airflow options.

Static Pass Box / Air Shower Pass Box

Interlocked Doors

Stainless Steel Inside

Used for material transfer and sterilization

FFU (Filtered Fan Unit)

Maintain Air Cleanliness

Create Laminar Airflow

Ceiling Installation Allow Space Efficiency

Variable Speed & Pressure Meter

Easy Operation Control Panel

Options available to install AC inside the cleanroom

For Cold Air Injection Temperature Control is Required

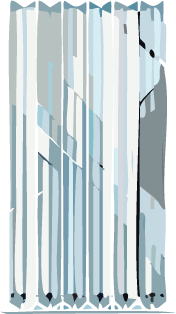

Air Shower

High Velocity Airflow

G4 + H14 Double Filtration

Automatic Air Shower & Time Adjustable

LCD Control Panel & Interlocked Doors

Easily Assembled Inside Any Space

These modular cleanrooms can be installed inside areas with air conditioning. They pull outside air from the ceiling into the cleanroom creating positive clean air pressure using HEPA filters.

LET’S WORK TOGETHER!

The Challenges of Traditional Cleanroom Construction

Traditional cleanroom construction faces several challenges.

It’s time-consuming, involving lengthy design, engineering, construction, and testing phases, impacting project timelines and potentially delaying production. On-site construction is complex and messy, risking contamination and requiring extensive cleaning.

Coordination among multiple contractors can be a logistical nightmare, leading to delays and errors. Costs are substantial, encompassing materials, labor, and equipment, with potential for overruns. Modifying or expanding a traditional cleanroom is difficult and expensive, limiting flexibility.

Finally, ensuring quality control is challenging due to conventional construction, necessitating thorough testing and validation.

About us

Aiko 8 LLC, based in Bonita, California, is led by founder Aiko Enriquez. Ms. Enriquez brings over 20 years of construction experience to the company, and recently completed a major pharmaceutical construction project in Tijuana, Mexico among many other projects.

Our Services

We not only source the precise products you require, but also conduct thorough inspections at multiple stages of production to ensure compliance and maximize your satisfaction.

WE WORK WITH

Our Clients

Unleash your creativity with us

If you have any questions send us a message and we will get back to you as quick as we can.